A positive displacement pump, called a chemical metering pump, often referred to as a dosage pump, injects chemicals or other substances into water, gas, or steam. Most metering pumps are tiny and offer precise flow rates for optimal control. They provide the foundation of a comprehensive metering system made for automatic chemical dispersion. They are pumps made to measure flow control and deliver precise fluid volumes. To transfer the fluid, they use chambers for expansion and contraction. Metering pumps can pump a wide range of liquids, including corrosive liquids, acids, bases, and viscous liquids, with extreme accuracy Read More…

Since 1886, John Blue has been a trusted pump company for agriculture and industrial applications. With over 136 years of experience, John Blue has gained a reputation as a quality manufacturer of piston metering pumps, 12-volt pumps and chemical injection pumps. We provide dependability and versatility, while serving various industries. John Blue pumps are “Guaranteed To Do The Job”.

Dewco Controlled Fluid Solutions has been serving industry with fluid metering and control equipment since 1974. With established product lines including metering pumps and solenoid valves among many other products, DEWCO provides quality components for both wholesalers and end users. Our complete system capabilities and repair services mean we can meet your every need quickly and efficiently.

LEWA is your global supplier of metering pumps, process diaphragm pumps and packaged systems. We strive for a close partnership with customers to ensure your complete satisfaction from initial consultation to continuing service and repair, spare parts supply, maintenance and training. A leader in highly precise and high performance pumps, LEWA works with you to find the best component for you.

As one of the oldest manufacturers of metering pumps, Randolph has maintained a loyal following by delivering "rugged, reliable and simple to use" products. Randolph machines all the components of its pumps to its exacting specifications and extrudes its own tubing. The Randolph pump can be found working in industries such as printing, food, pharmaceutical, nuclear and wastewater.

More Chemical Metering Pump Manufacturers

Factors to Consider When Choosing a Chemical Metering Pump

Although the definition of a metering pump sounds fairly clear, the criteria for selecting the best pump rely far more on the application. There can be wide variations in maximum flow rate, maximum pressure, supply voltage, the type of control used, and material compatibility.

Maximum Flow Rate

A pump one requires can be determined by how much chemical solution needs to be added to the process in gallons or liters per hour. Metering pumps with lower maximum flow rates are typically easier and less expensive than other pumps. Some applications, such as smaller factories, require a chemical dosing pump to adequately treat their water before it leaves their plant to comply with local regulations. The pump requirements for these smaller facilities are usually low. Metering pumps are an example that works well for smaller manufacturers who don't require big outputs, with a 3.2 gallon per hour output.

However, some applications, such as those in agriculture or water treatment plants, call for higher outputs from more expensive metering pumps. However, a higher maximum flow rate puts the pump under additional strain and wear. High-output chemical dosing pumps will frequently have extra features to handle this and increase the performance of the pump's longevity.

The roller bearings and oil bath lubrication on the chemical metering pump ensure durability and wear resistance during extended use. A chemical metering pump with high output and stable features is often the best choice for demanding water treatment or greywater procedures.

Maximum Pressure Range

Large pressure ranges may logically correspond with high flow rates for flow instrumentation. However, this is only sometimes the case for metering pumps. Consider the example of pumping chemicals into a pressurized mainline at a water treatment plant. Although the water treatment metering pump's pressure range is relatively high, the flow rate required for chemical injection is quite low. This process may be done to achieve highly exact pH, chlorine, or other water quality parameter balancing.

Additionally, higher pressure ranges frequently necessitate additional characteristics for the pump's stability. For example, a bearing at each end of the pump's armature and shaft enables proper axial movement even when the pump operates at high-speed rates, such as 360 strokes per minute. This design guarantees chemical feed with great resolution across a wide range of applications.

Types of Chemical Metering Pumps

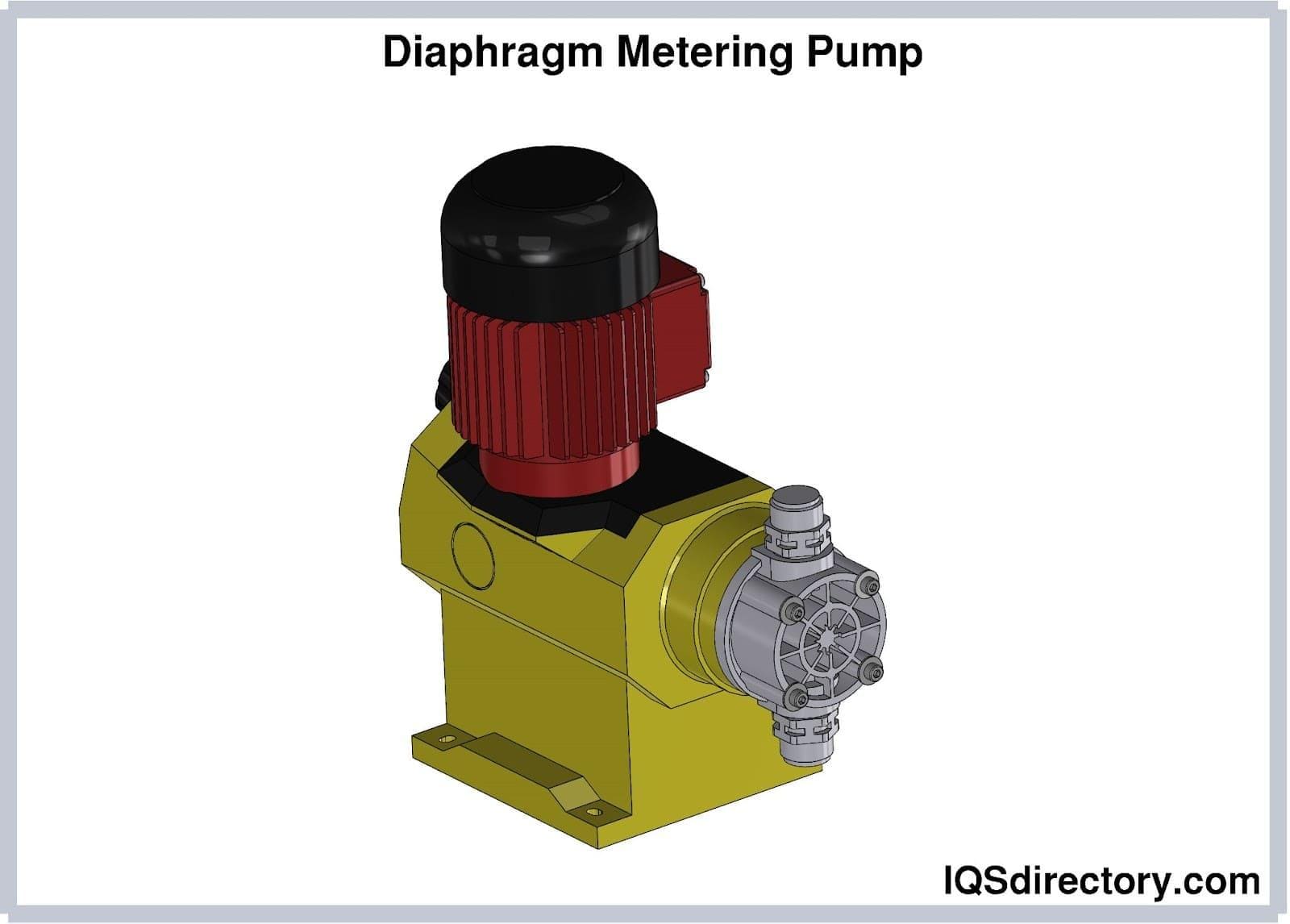

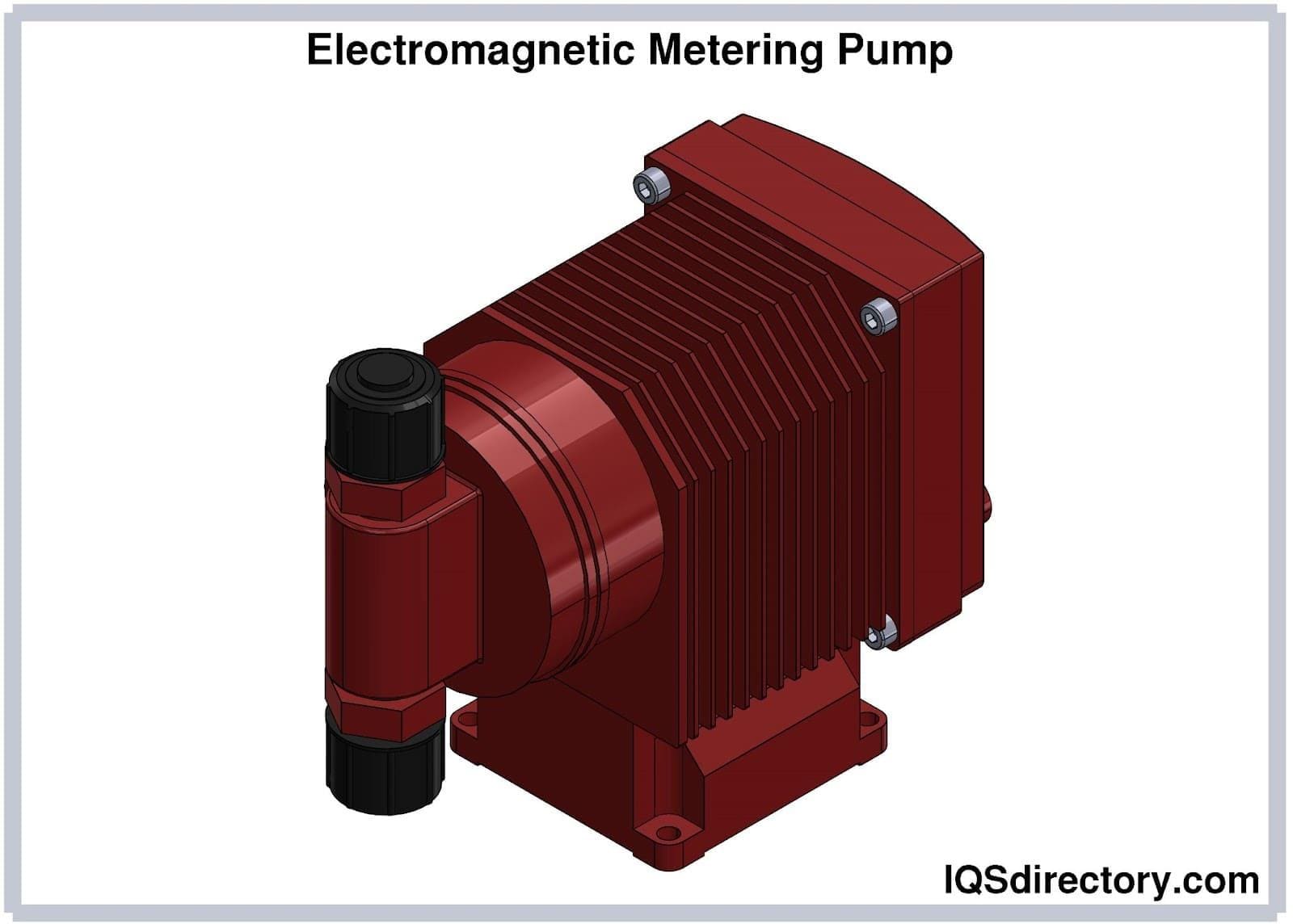

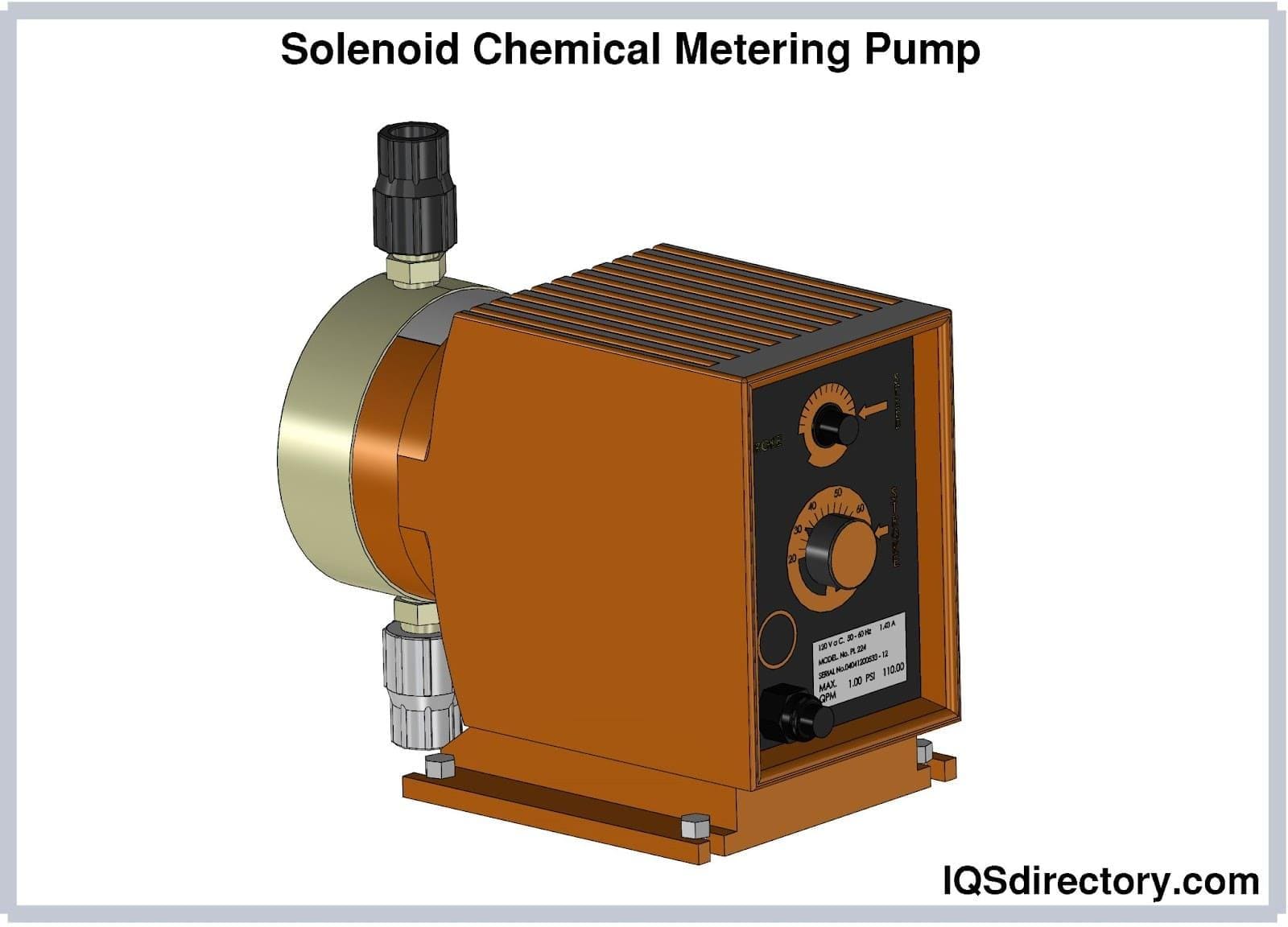

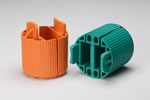

There are numerous types and sizes of metering pumps. A metering pump is ideal for the job, whether used in food processing applications, manufacturing operations, or anywhere else where a liquid needs to be pushed in consistent and accurate amounts. The four common metering pumps were created to handle various pressures, chemicals, and applications. However, by pumping action and mechanism, they differ:

Constant injection diaphragm pumps fill and empty their chambers using pistons, diaphragms, and valves at the inlet and output. When the piston is pumped, the chamber is filled, and a predetermined amount of chemical is injected at a predetermined rate, typically expressed as a percentage of the maximum flow rate. The dose rate can be changed in some pump models.

Additionally, using a diaphragm mechanism, a solenoid coil draws in the chemical and pulse-injects it in the case of diaphragm (pulse jet) pumps. The interval between pulses is the flow rate. Although it is less precise than a constant injection pump, the design is straightforward and low-cost.

A nozzle pump allows a specific amount of fluid to flow via an impeller with meshing. It only works with high-viscosity fluids that have a self-lubricating effect of reducing wear, making it less precise than a diaphragm pump. Low flow rates are not suitable for them since it is difficult to ensure precision.

Metering with peristaltic pumps is extremely precise. The fluid can pass through the flexible, bent tube, and a roller manipulated by an external robotic arm regulates the flow rate. Finally, the substance in the tube is pushed into the metering tube and the main fluid stream.

Method of Control

Operators have access to a wide variety of controls, similar to most flow instruments, depending on what is required for their application.

Manually controlling the stroke length is best for simpler applications when the process is very predictable and can be set and forgotten; there is no need for a flow controller. Other chemical metering pumps may require control of digital input. This is an improvement over "set it and forget it" pumps and is ideal for predictable applications. A flow controller can change the feed rate based on the pulse rate.

For more demanding applications where automation and control from a central place without walking to each pump is a top priority, 4-20mA analog input control is perfect. It allows for high-resolution chemical feed and utilizes the pump's whole operating range with a flow controller. Additionally useful for local governments who already have to keep track of numerous water quality indicators like pH and TDS.

Choosing the Right Chemical Metering Pumps Supplier

To make sure you have the most constructive outcome when purchasing Chemical Metering Pumps from a Chemical Metering Pumps Supplier, it is important to compare at least 5 or 6 Suppliers using our list of Chemical Metering Pumps manufacturers. Each Chemical Metering Pumps Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Chemical Metering Pumps business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Chemical Metering Pumps companies with the same message.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services